Container emptier

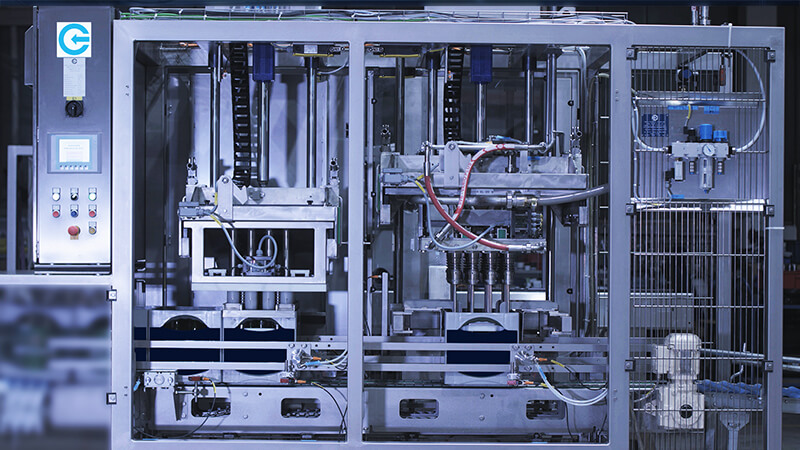

What to do with rejected bottles or cans after filling, capping or labelling? The EV940 single bottle emptier offers a hygienic and efficient solution for underfilled, mislabelled or otherwise rejected containers.

EV940: Opening and emptying on the bottle conveyor

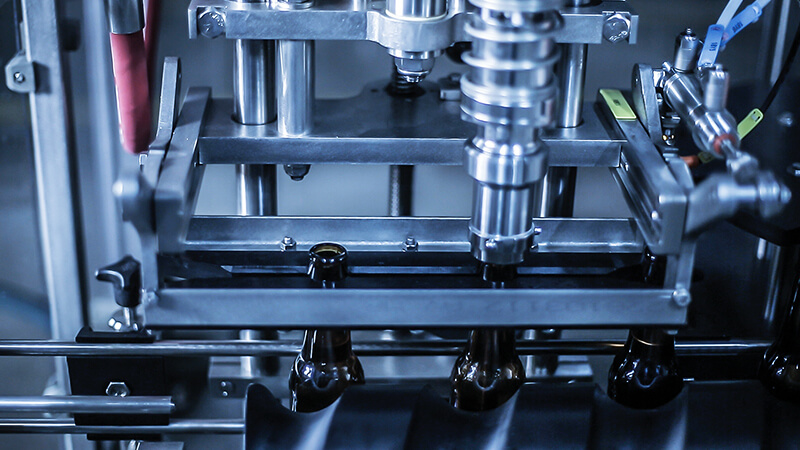

The liquid is pressed out of the bottles or cans with overpressure via special emptying valves and discharged via a collecting pipe – hygienically, economically and with minimal oxygen pick-up. The risk of reinfection remains extremely low. Your products retain their usual quality and can be reused – reducing losses and increasing the efficiency of your system.

Depending on your requirements, we configure the system individually for your application. Please contact us with your specific requirements – we will provide you with the right solution.

Questions about our customised products?

Dr Michael Bäcker

The EV940 is flexible, user-friendly and customisable. The system is made entirely of stainless steel and is CIP-capable.

Opening and emptying glass or PET bottles and cans

Complete and hygienic recovery of the contents

Minimum oxygen uptake

Short changeover times

Low maintenance

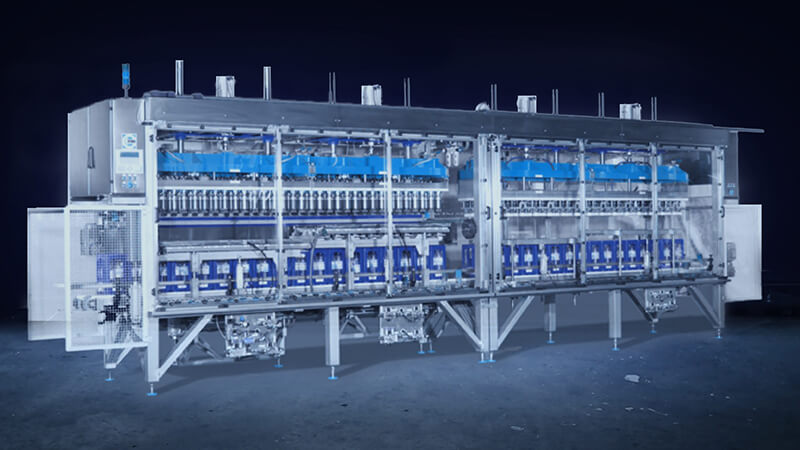

Other special designs for the beverage industry

Special machine construction from RINK