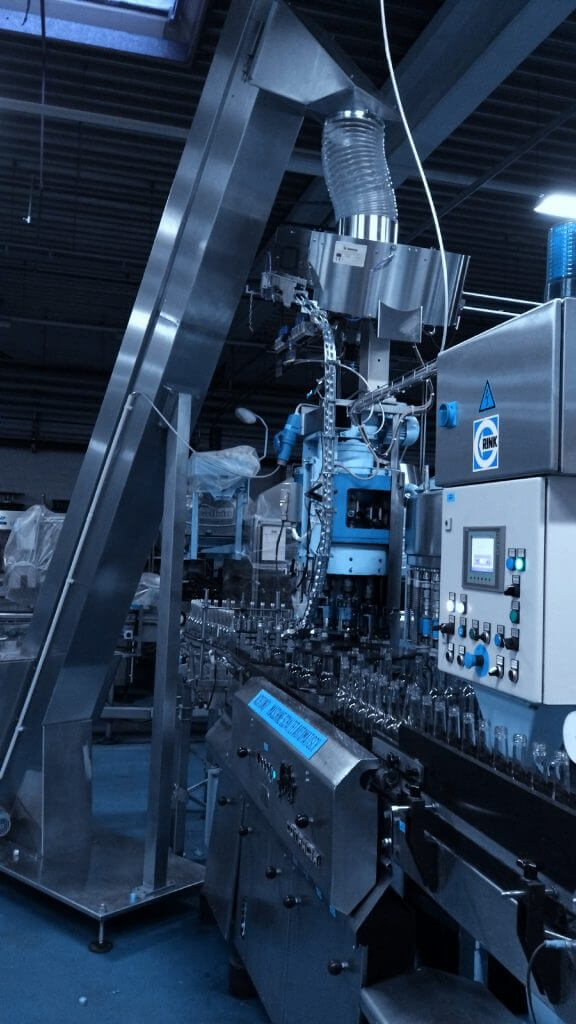

Semi-automatic capping machine

H1

Semi-automatic capping machine for cylindrical and moulded bottles

Capping of all common bottles

The H1 closes cylindrical and moulded bottles of your choice in manual mode. As a tabletop machine, it can be used anywhere. The measuring tape on the back makes it easy to adjust to different bottle heights. You can easily control the capping process with the jog function. The coupling of the lifting and rotating movement via an electric drive guarantees a reliable capping process.

The most important key data

Semi-automatic capping machine type H1

| Bottle shape | Cylindrical and moulded bottles |

| Bottle height/diameter | from 120 mm to 400 mm |

| Closure types | all common closures from 28×15, 28×44, 30×60, 31.5×18 etc. (also with spout) (also with spout) |

| integration | Table machine |

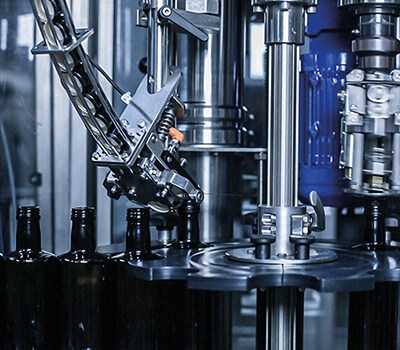

| Capping process | 1.6 turns at the lower operating point as required by cap manufacturers |

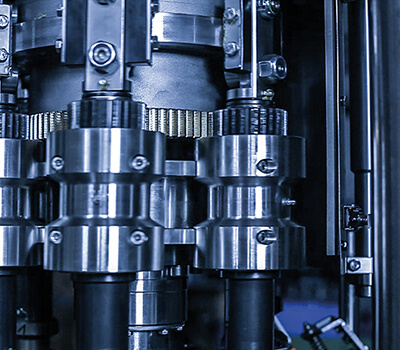

| Capping head | High-quality capping head, 2 thread rollers / 2 crimping rollers, no closure – no contact (safety plunger) |

| Format change | Height easily adjustable by measuring tape on the back |

| Capacity | Operator-dependent, approx. 1000 bottles/hour |

| Sorting unit | No infeed |

| Special features | Inching mode |

| options | mobile table, transport frame |

Questions about our cappers?

Your contact person:

Dr Michael Bäcker

Dr Michael Bäcker

Our customer projects and application examples

Solutions for sealing

Our capping machines & services at a glance

1-head capping machine

VS1

Multi-head capping machine

VRA