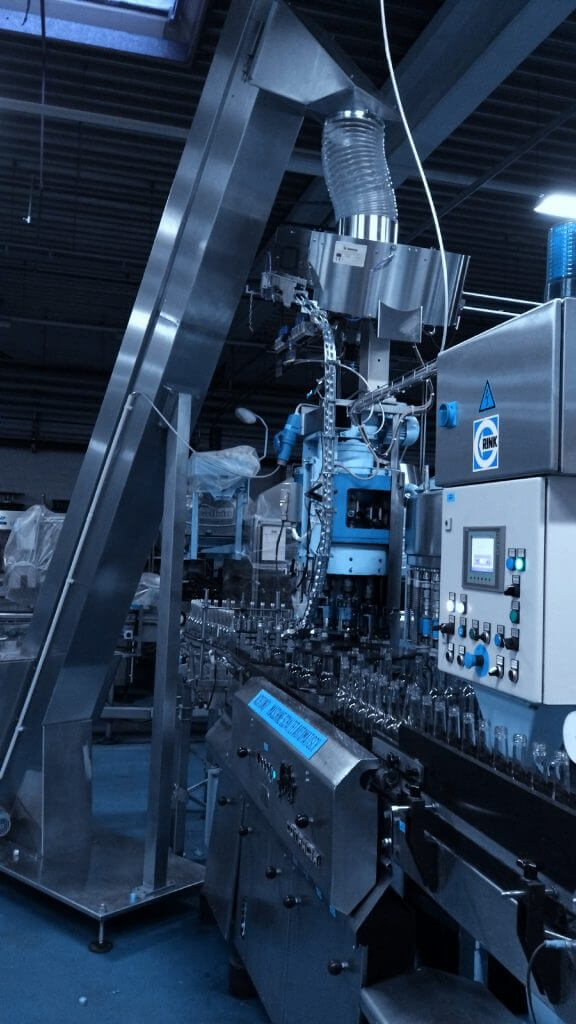

1-head capping machine

VS1

1-head capping machine for cylindrical and moulded bottles

Capping of all common bottles

The VS1 closes up to 3,000 bottles/h and is suitable for a wide variety of roll-on closures. The coupling of the lifting and rotating movement via an electric drive guarantees a reliable capping process. The bottle guide on the neck enables precise positioning of the bottle under the capping head, even with large bottle tolerances. It is very easy to change between different cap types.

The most important key data

1-head capping machine Machine type VS1

| Bottle shape | Cylindrical and moulded bottles |

| Bottle height/diameter | from 120 mm to 400 mm |

| Closure types | all common closures from 28×15, 28×44, 30×60, 31.5×18 etc. (also with spout) (also with spout) |

| Integration | Easy to integrate into existing belt, no separate belt drive |

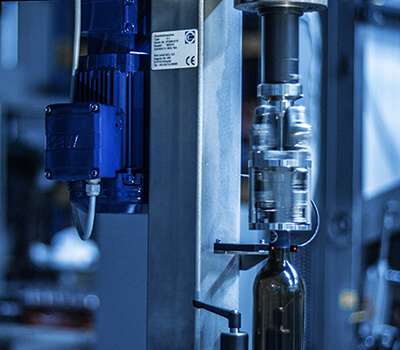

| Sealing process | 1.6 turns at the lower operating point as required by cap manufacturers |

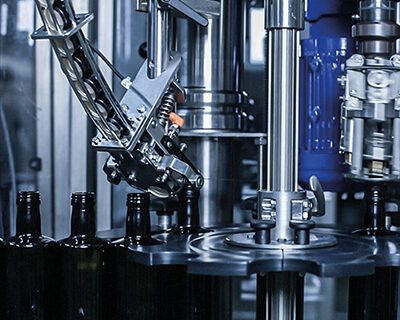

| Capping head | High-quality capping head, 2 threaded rollers / 2 crimping rollers, no closure – no contact (safety plunger) |

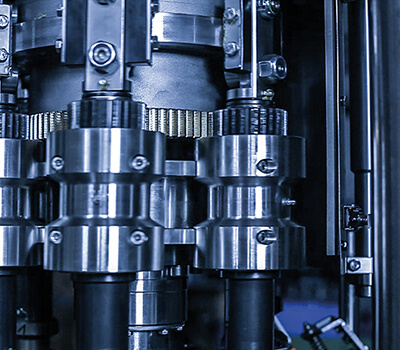

| Format change | Height easily adjustable by reference bottle on bottle disc, simple format parts, neck star is adjusted with upper part |

| Output | up to 3,000 bottles/hour |

| Sorting unit | Air sorting unit |

| Special features | Mechanically coupled electric drive for capping and lifting movement, neck guide mounted on the upper part, hygienic design with drive from above |

| options | CO2 overlay, feeding with elevator, air filter, electrical height adjustment |

Questions about our cappers?

Your contact person:

Dr Michael Bäcker

Dr Michael Bäcker

Our customer projects and application examples

Solutions for sealing

Our capping machines & services at a glance

Semi-automatic capping machine

H1

Multi-head capping machine

VRA