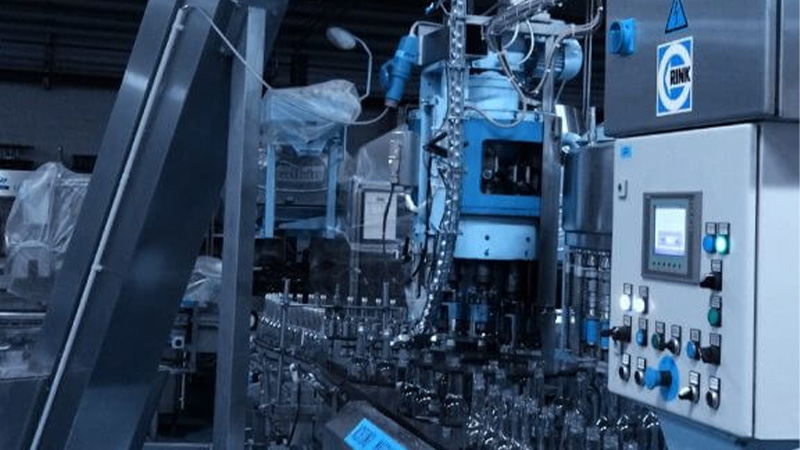

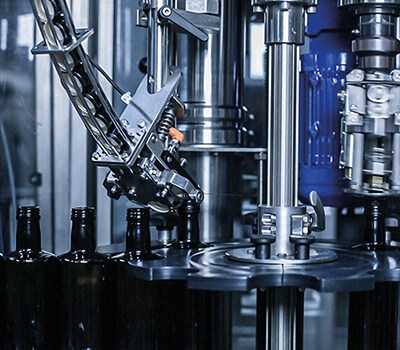

Capping machines for the beverage industry

Sealing bottles with RINK

High reliability – low wear, i.e. more productivity – that is what characterises our cappers. From semi-automatic to single-head and multi-head cappers – please contact us directly for the right solution for you:

Our solutions at a glance

The capper

With the introduction of the one-way deposit in 2003, the reusable system and thus RINK's traditional clientele came under pressure. In the meantime, Dr Michael Bäcker, the 3rd generation, was successfully working in the family-run company. Together with his father, Jochen Bäcker, the decision was made to broaden the company's market position. The product programme was therefore expanded to include capping technology. Today we can offer 3 machine types as well as comprehensive service including conversions of third-party machines:

Semi-automatic capping machine

H1

1-head capping machine

VS1

Multi-head capping machine

VRA

Capping heads & retrofits

machine service

Advantages of our machines

What cappers from RINK offer

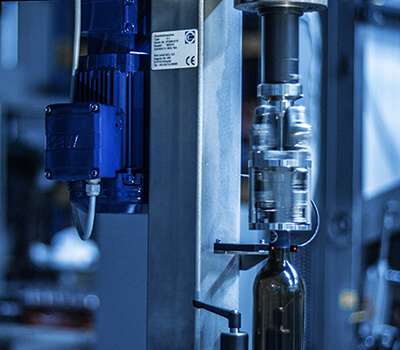

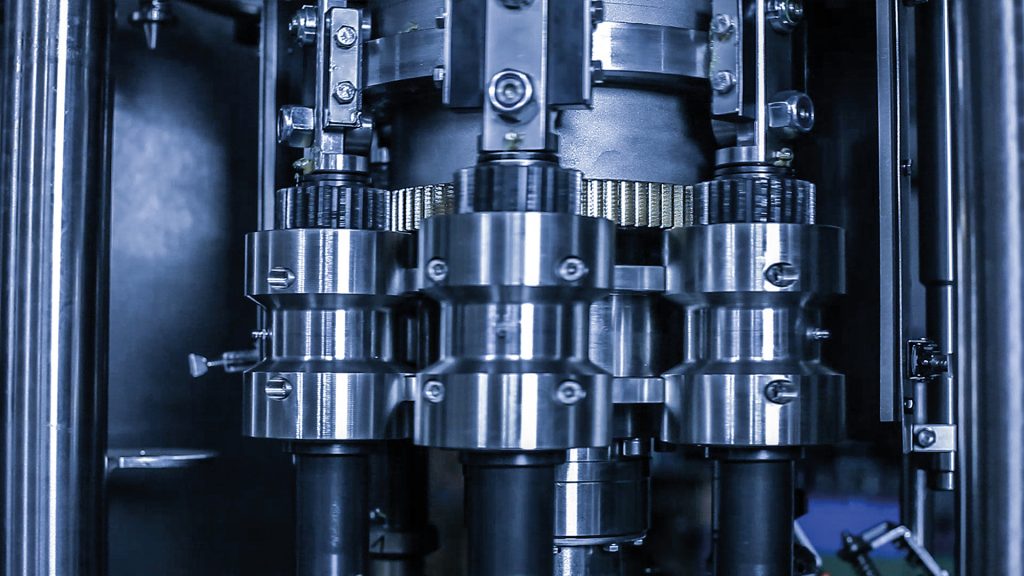

Reliable capping process

Simple format change

Low-maintenance and solid construction

Complies with the currently valid CE directives

Questions about our cappers?

Your contact person:

Dr Michael Bäcker

Dr Michael Bäcker

RINK machines for capping bottles

State-of-the-art technologies for the beverage industry

The first capping machines were sold in 2006. The aim was to tap into new customer groups and establish itself on the market not only as a specialist for opening bottles, but also for capping them. The company can now look back on almost 20 years of experience in capping technology and is a successful supplier of the following machine types:

Semi-automatic capper

The H1 effortlessly closes all bottles for aluminium roll-on closures. With electric drive for lifting & capping movement and inching operation, suitable for short and long cap closures. Find out more about the application and machine data:

1-head capping machine

The VS-1 closes bottles with all standard roll-on closures. The machine can be easily integrated into an existing conveyor - we will be happy to advise you on your individual requirements.

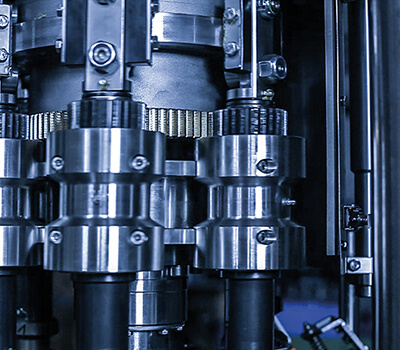

Multi-head capping machine

The VRA caps bottles in a rotary motion using 3-8 capping heads, depending on your individual requirements. Depending on the number of heads, the output range is 4,000 to 16,000 bottles/h, suitable for short and long caps. Application examples and further information can be found here:

Our customer projects and application examples