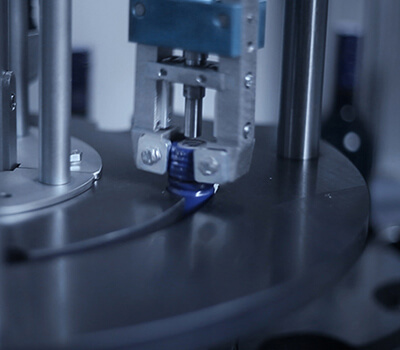

Decapper for the beverage industry

Remove screw caps with RINK

With unscrewing machines from RINK, you get compact machines for removing screw caps. We guarantee reliable and efficient unscrewing processes on the bottle conveyor or directly in the crate – gentle on the bottle and reliable. Let us advise you:

The decapping machines

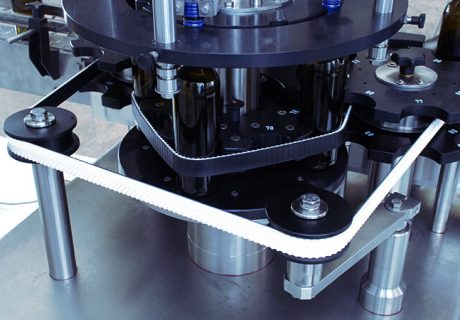

Crate decapper

KM790

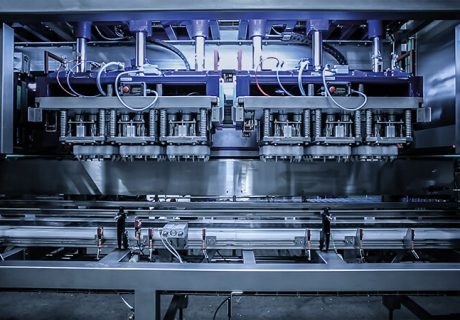

Single bottle decapper

ESR

Advantages of unscrewing machines for the beverage industry

Since the company was founded, the RINK team has been constantly working on developing new machines to meet all of our customers’ challenges. With the crate decapper, we have been offering an alternative to the single bottle decapper for decades in order to be able to dispense with the costly and space-intensive bottle separation after the unpacker in front of the washing machine. This also has a very favourable effect on the bottle buffer between the unpacker and washing machine. Incidentally, it can be perfectly extended to include the decrowning function.

With a large variety of formats and poorly sorted empties, the advantages lie with the single bottle decapper, which we have also had in our product range for years. Recently also for large closures in the dairy sector, such as yoghurt jars and milk bottles.

Crate & Band

Unscrewing & uncorking

Efficiency & reliability

Reusable & recycling

Questions about our unscrewing tools?

Dr Michael Bäcker

RINK machines for unscrewing closures

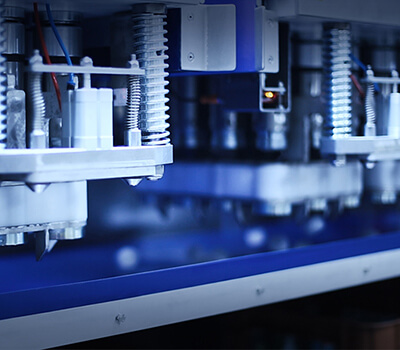

State-of-the-art technologies for the beverage industry

Since the company was founded, the RINK team has been constantly working on developing new machines to meet all customer challenges. We are the only supplier in the industry worldwide for both crate and single bottle unscrewing machines.

Our customer projects and application examples

Decapping machines from RINK

1973

The development of the decapping machines

Soon after the market launch of the decrowner, customers made the request to RINK to decap bottles in crates. Until this time, screw caps were exclusively removed on the bottle conveyor.

With the introduction of the crate decapper, we surprised our customers with a space-saving solution in front of the unpacker.

2001

RINK extends the unscrewing function for PET bottles to include a second process, that of regeneration.

2010

RINK develops the first unscrewing device for individual bottles.

2023

RINK offers a unscrewing device for large closures in dairies.